An enormously successful enterprise, in the 45 years since the company was established by Alan Willmot, Willmot Smash Repair has grown from a small shop with a handful of staff to be a business that incorporates two state-of-the-art, purpose-built workshops manned by nearly 40 highly trained staff, moves around 100 vehicles a week through its doors and has a turnover of $15 million a year.

Those numbers are truly impressive, and Wes and partner and co-owner Helena Willmot, daughter of Allan, have shepherded the business since buying it a decade ago to become an enterprise that is regarded as one of the very best in the repair industry.

For Wes, investing in the buildings, the equipment, and the training of his staff made sense as he and Helena looked to ensure the business was an industry leader that could adapt to the evolution of the motor vehicle, the new materials being used in their construction, and the technology – especially high-voltage electrical and battery systems – that underpins many of the vehicles coming to the market.

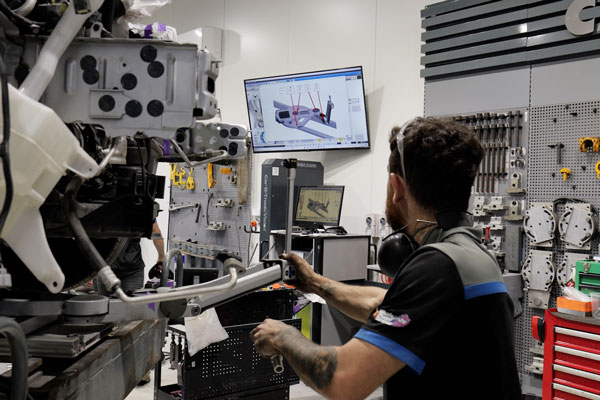

“I’ve been in the industry 28 years . . . and it is such a high-tech trade today,” said Wes. “Here we are working with laser measuring equipment, computer temperature-controlled spray booths, water-based paint, air-fed masks, and we are working in air conditioning.

“Repairing a car is nothing like it used to be,” he added with a smile. “Everything is high tech. From the steels that you’re working with to the EVs we have to decommission to work on safely. And you go home clean as a whistle! It’s a far cry from where it started, that’s for sure.”

Wes’ own journey to business owner is a classic example of the journey of someone who knew the industry in which they wanted to work, could see where things could be improved, and had the ambition to be one of its leaders.

“I started when I was 15 years old,” he said. “On the way home on my last day of school I rode straight to a panel shop and asked for a job as a spray painter. They said, ‘Mate, can you start Monday?’

“Back in those days, it was a pretty crude and dusty environment and there was not too much fancy equipment. But we repaired cars, and I loved it . . . From there, I finished my apprenticeship and moved to Brisbane to pursue a motorcross career. I bought myself a little body shop thinking I’d have more time, but it turned out I love business.

“I decided to move back to Cairns and started my career with Willmot Smash Repairs as a contractor. It was here that I really worked out where technology was heading in the industry. I worked here for around 18 years . . . bought it with Helena and we grew from eight staff to nearly 40 staff today and we’re a $15 million turnover business.

“That’s not too bad for a young bloke who started out by riding into a shop on his pushbike.”

As with all other sectors within the automotive industry – and indeed most industries – the search for skilled staff and apprentices is a challenge. For some sectors, including vehicle repair, the challenge is not just about numbers but about perception: many people see it as one that is grimy, tough, dusty and generally unpleasant for much of the time.

Add to that is the difficulty some people have in recognising just what a career in vehicle repair, or any auto industry sector, can mean. Mechanic, panel beater, painter, auto electrician – these words might describe a trade, but they do not

describe a career.

The best of the modern vehicle repair sector, exemplified by businesses such as Willmot Smash Repair, are worlds away from the image of a dusty, dirty, workshop, and Wes is keen, for young people especially, to grasp that completing a panel beater or paining trade is the first step on a career that will challenge them; expose them to some truly high-tech equipment and machinery; enable them to work on, repair, and understand the cutting-edge vehicles entering the market; and give them the opportunity not only to earn extremely good money, but pursue business ownership ambitions too.

“What excites me about the industry these days is how professional it has got, how high-tech it is and what we get to work with these days,” said Wes.

“EVs are something special and that’s a pretty cool sector in the industry. Aluminium vehicles, carbon fibre vehicles, high-tech carbon steels – it’s really going places, and you can see by the number of shops being built and how professional they have become that there is a bright future for our industry.

“Also cool is the career progression it can provide. You can work your way from being an apprentice all the way up to an operations manager, an estimator, a foreman, a body shop owner.

“And this industry also gives you an awesome hobby. If you’re building something cool out there – a street machine or hot rod – you learn so many skills that you can adapt to that hobby.”

For those looking for that challenge, for that career that offers plenty of potential, the paint and panel industry is one that deserves a close look, said Wes.

“It’s challenging. It’s exciting. It’s high tech. It’s clean and it’s extremely well-paid,” he said. “So reach out to your local repairer, come down and have a chat. If you turned up at my front door, I’d want to talk to you. Not every shop’s going to look as shiny as this one, but once you get your foot in the door, the world is your oyster.”

APPRENTICESHIP OPENS DOOR TO CAREER WITH POTENTIAL

Getting his foot in the door is exactly what happened to Toby Atkinson, an 18-year-old apprentice working at Willmots. Toby is, in fact, taking on a dual apprenticeship – both paint and panel repair – and kicked things off back in 2022 when he signed on with Willmots as a school-based panel

repair apprentice.

Being a school-based apprentice was, said Toby, a terrific experience, giving him the opportunity to finish school while simultaneously learning a trade and earning some money. Working full time, meanwhile, has allowed him to fully appreciate what the trades have to offer.

“Until I finished year 12, I was at school Monday, Tuesday, Wednesday, while Thursday and Friday I was at my apprenticeship. Once I got my Year 12 certificate, I walked straight into a full-time job,” he said.

“I’m not someone who can just go to work and go home every day without a bit of fulfillment and, for me, both of the trades are perfect for that. There are limitless opportunities . . . If you want to put in the work, you want to learn,

you can do anything you want.

“. . . One of the technologies we have in the shop is electric vehicles and a couple of things we do is depowering and reinitialising them. They are going to be everywhere soon and I’m here now learning how to do it. It’s an investment in yourself to learn how to work on electric vehicles because the industry’s about to get so much larger . . . and you’re going to be right in the centre of it as a panel beater.”

Working at Willmot is, said Toby, pretty special, and while not all shops are going to offer the range of work or access to such cutting-edge facilities, the paint and panel trades offered the chance to be creative and learn skills that would be highly valued.

“Willmots is a very high-tech workshop with super sophisticated machinery and really complex repairs get done here,” said Toby. “. . . The training here is fantastic, the support here is fantastic, and I know that the pathways for a lifelong career are wide open. I’d recommend Paint and panel for anyone who loves cars and has an eye for detail. If you’re creative, then it’s for you. Just do it!”

Source: Motor Trader (September 2024)

12 September 2024