The use of humanoid robots may seem like something one might see only in science fiction, but technology can move at quite a clip and, last month, the BMW Group revealed it is exploring the use of humanoid robots in production for the first time.

Together with Figure – a California-based robotics company – the BMW Group is evaluating how such robots can be used safely in vehicle production.

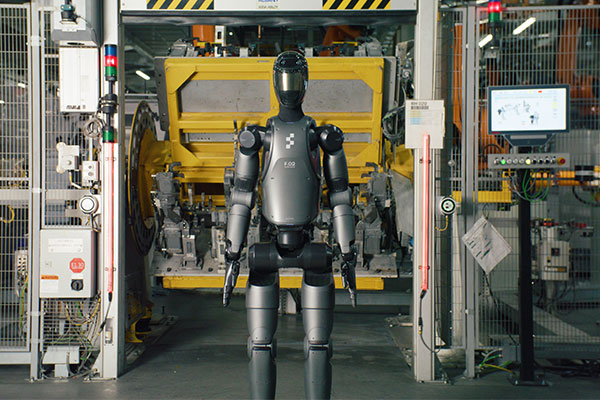

During a trial run lasting several weeks at BMW Group Plant Spartanburg in the U.S., the latest humanoid robot from Figure – called the Figure 02 – successfully inserted sheet metal parts into specific fixtures which were then assembled as part of a chassis.

According to Figure, the combination of two-legged mobility and advanced dexterity means that the Figure 02 is ideally suited for use in areas with physically demanding, unsafe, or repetitive processes. The company says the robot is capable of fully autonomous execution of human-like and two-handed tasks requiring varied and dynamic manipulation, complex grasping, and coordination of both hands in unison.

“The developments in the field of robotics are very promising. With an early test operation, we are now determining possible applications for humanoid robots in production. We want to accompany this technology from development to industrialisation,” said Milan Nedeljkovi, Member of the Board of Management for Production at BMW AG, in a media release.

During the trial, the BMW Group says it gained valuable knowledge of what requirements must be met in order to be able to integrate so-called multi-purpose robots in an existing production system. The company said it will continue to collaborate with Figure on future applications in production and development of the robots, and work with Figure for data capturing and training capabilities for the Figure 02 robots.

Source: Motor Trader e-Magazine (September 2024)

11 September 2024